Biofunctionalized Materials — Successfully Incorporating Enzymes into Plastics

Fraunhofer Research in Brief | Plastics are usually processed at well over one hundred degrees Celsius, enzymes, on the other hand, usually do not withstand these high temperatures. Researchers at the Fraunhofer Institute for Applied Polymer Research IAP have succeeded in bringing these opposites together: They can incorporate enzymes into plastics without the enzymes losing their activity. The potential that results from this is great.

Materials that clean themselves, have anti-mold surfaces or can even degrade themselves are just a few examples of what becomes possible when it is possible to incorporate active enzymes into plastics. However, in order for the enzyme-specific properties to be transferred to the materials, the enzymes must not be damaged during installation in the plastic. Scientists at Fraunhofer IAP have developed a solution for this as part of the “Bio-functionalization/biologization of polymer materials BioPol” project. Since summer 2018, the project has been running in cooperation with the BTU Cottbus-Senftenberg. It is funded by the Ministry of Science, Research and Culture of the State of Brandenburg.

“It was clear from the outset that we were not interested in the production of biofunctionalized plastics on a laboratory scale. We wanted to go big right away to show that technical production is possible.” This is how Dr. Ruben R. Rosencrantz, head of the department “Biofunctionalized Materials and (Glyco)Biotechnology” at Fraunhofer IAP, summarizes the ambitious goals of the project. Even now, after about half of the service life has passed, great successes are evident: With regard to both the enzymes themselves and the processing process, the integration of enzymes has been successful.

Higher temperature stability due to inorganic carriers

The search for a way to stabilize the enzymes led the researchers to use inorganic carriers. These represent a kind of protective armor for the enzyme, explains Rosencrantz: “For example, we use inorganic particles that are very porous. The enzymes bind to these carriers by depositing themselves in the pores. Even if this restricts the mobility of the enzymes, they remain active and can withstand significantly higher temperatures.”

Rosencrantz emphasizes, however, that there is no universally valid stabilization process: “Every enzyme is different. Which carrier and which technology is most suitable for loading it remains enzyme-dependent.”

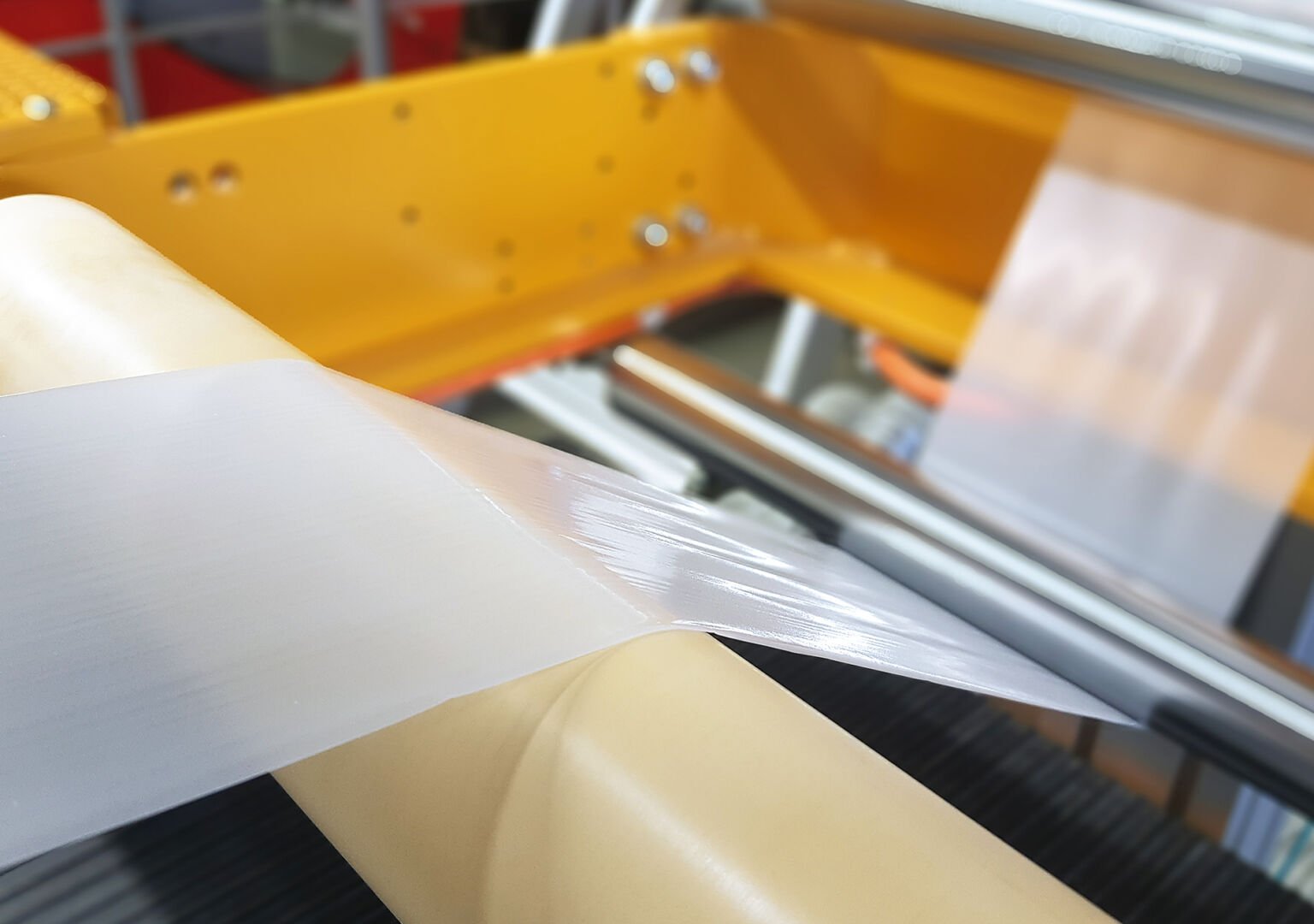

Production of a biofunctionalized film in the processing pilot plant. © Fraunhofer IAP

Stabilized enzymes: not only on the surface, but also inside plastics

The researchers deliberately looked for a way not only to apply the stabilized enzymes to the surface of the plastic, but also to incorporate them directly into the plastic. “This is much more difficult, but even signs of wear and tear on the material surface cannot affect the functionality of the plastics,” explains Thomas Büsse, who heads the institute’s own processing technology center for biopolymers in Schwarzheide.

In order to obtain an optimal material result in the further processing process, the stabilized enzymes must be distributed as quickly as possible in the hot plastic melt to which they are added, without the force or temperatures becoming too high. A balancing act, the result of which Büsse is satisfied with: “We have developed a process that is suitable for both bioplastics and classic petroleum-based plastics such as polyethylene. In addition, our investigations show that stabilized enzymes are able to withstand even higher thermal loads after being incorporated into the plastic than they were before processing. This makes the use of the enzymes and all process steps much easier.”

Self-cleaning plastics are just the beginning

So far, researchers at Fraunhofer IAP have mainly focused on proteases when it comes to the choice of enzyme. These can split other proteins. This gives the plastic functionalized with them a self-cleaning effect. For example, pipes could become less easily overgrown or clogged. But other enzymes are also systematically tested. The cooperation partners at the BTU Cottbus-Senftenberg, for example, are increasingly dealing with enzymes for the degradation of plastics and for the degradation of toxic substances.

The first functionalized plastic granules, films and injection-molded bodies have already been produced. The researchers have proven that the enzymes incorporated in them are still active. In the next step, the suitability for everyday use in various applications will be tested and further optimized. Rosencrantz and Büsse are optimistic – and have now also filed a patent application for their research.